Ligne 2

The Line x RATP la ligne

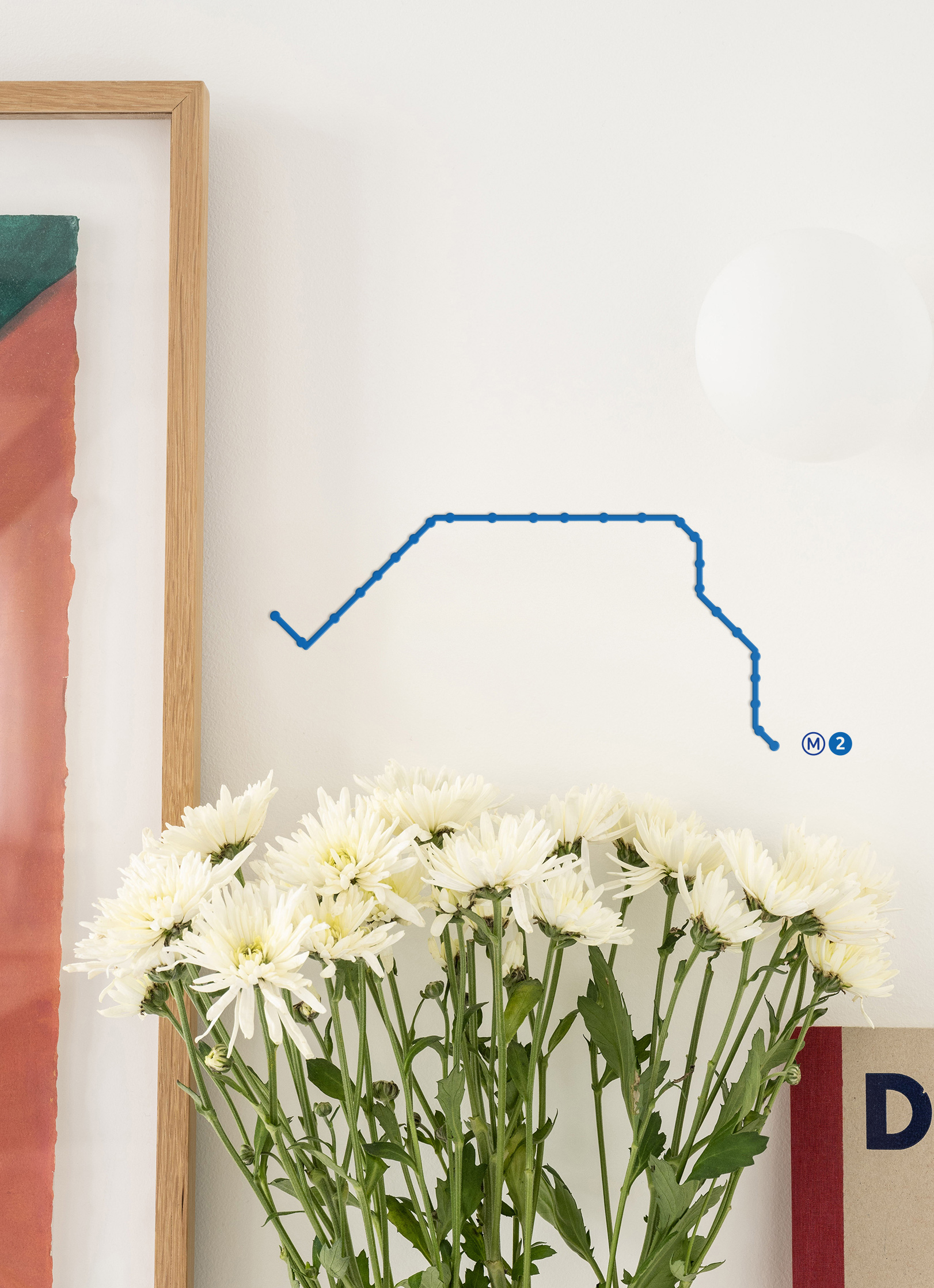

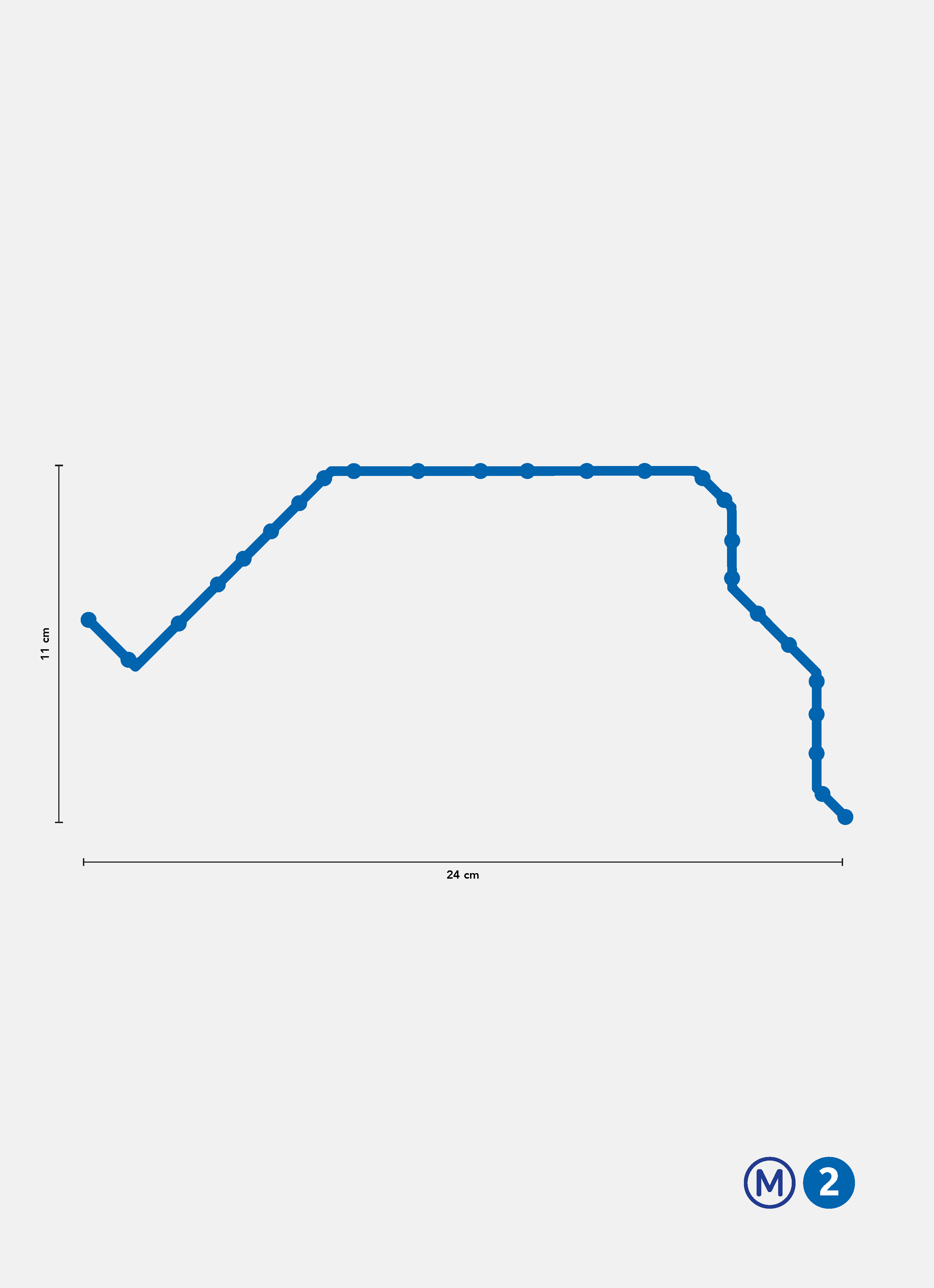

We have depicted the route of line 2 of the Paris subway and its 25 stations.

With this new format, it is possible to stick, magnetize and even place the line anywhere thanks to its cardboard support on which the names of the stations appear.

The Line x RATP is made in France.

Find out more about Ligne 2Any order placed before 11:30am (UTC+1) is shipped the same day (except weekends).

Delivery in France in 2-5 working days.

Shipping costs offered in relay points in France.

Indications

-

1.5 mm thick steel line

-

To be wall fixed with 3 nails

-

Inside and outside

-

Super easy

-

Start by nailing the middle of the line, then simply adjust the level

-

Not suitable for brick or concrete walls

Between Porte Dauphine and Place de la Nation, line 2 forms an arc serving the north of Paris. Built on the route of the Fermiers Généraux wall demolished in 1860, it opened in sections between 1900 and 1903. Part of its route was built as a viaduct to facilitate crossing the railway tracks of the Gare du Nord and Gare de l'Est stations, and to pass over the Canal Saint-Martin. The overhead stations of line 2 have a remarkable architecture: the platforms are lined with glass walls and are protected by a canopy supported by a metal openwork framework without pillars, a real architectural feat that reveals the light and luminous elegance of these stations.